ILC Auto Lubrication Systems

|

ILC MAX The ILC Max is the most universal, cost effective and reliable automatic lubrication system available. It is available in several sizes from 2kg, 4kg and 8kg and a choice of 12V, 24V or 240V suitable for oil and grease, with or without timer.Read More about the ILC MAX (Manual, Spare Parts, Installation Photos) |

|

|

ILC Mini Max The Mini-Max electric pump was designed to work both as a multi-outlet system and with DPX progressive distributors. Naturally both systems can also be combined. It is driven by a 12 V DC or 24 V DC gear motor and is capable of pumping grease with a max consistency of NLGI 2. The ILC Mini Max can be supplied with or without a Timer.ILC Mini Max Manual |

|

|

|

ILC DUAL LINE SYSTEM (ILC TWIN PUMP) The electric TWIN-PUMP has been designed for all applications that use Dual Line Systems. This pump is generally used on medium and large sized machinery and equipment that operate in harsh or extreme operating conditions for the various points to be lubricated. The systems can be very complex and longer than 100 metres. Any type of system can be designed and set up in a reliable, efficient manner, with the possibility of expansion. The system is available in either a 30kg or 100kg tank. All grease valves and accessories are available see more |

|

|

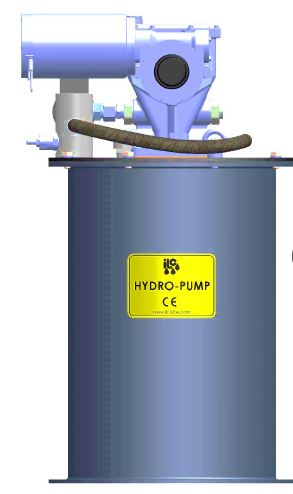

ILC HYDRA CAT High-performance HYDRO-PUMP rotary driven is a fully hydraulic operated adjustable grease pump with the output adjustable from 120 to 400 cc/1’. Grease output is proportional to the hydraulic input flow. The pump is primarily designed for centralised lubrication systems such as the single progressive line, injector and dualine systems. A 24 V DC solenoid valve is also incorporated. |

|

ILC ELECTRA CAT High-performance ELECTRO-PUMP combine rotary-driven pump motors with reciprocating pump tubes and flexible control features that perform in desert heat and arctic cold. The pump’s output is 200 cc/1’ ELECTRO-PUMP rotary driven is a electric grease pump. The pump is primarily designed for centralised lubrication systems such as the single progressive line, injector and dual line systems. A 24 V DC solenoid valve is also incorporated. |

|

ILC Also manufacture the following lubrication systems:

Volumetric lubricationConsisting of manual or automatic pumps combined with volumetric metering valves, the ILC volumetric lubrication system can measure oil or grease. Normally installed in industrial machinery, it also allows for lubrication in systems with several points. You can control pump operation and circuit integrity. Resistive LubricationIt is the ILC basic system that can dispense only oil and, combined with manual or automatic pumps, the DPT resistive metering units allow for continuous or intermittent lubrication depending on the metering and type of supply. Particularly suitable for agricultural overhead contact lines and small systems Minimal LubricationThe minimal ILC LUBETOOLS units are designed to lubricate removal-deformation operating tools and rotation and movement components with a minimum amount of lubrication. The advantages derive from the elimination of emulsions by improving processing and extending tool life Air/Oil LubricationThe ILC SPINDLE systems are designed to lubricate bearings and components that rotate at high/very high speeds. They are usually applied to lubricate bearings in electric spindles and mechanical processing heads. Combined with their control, they fully detect system operation Multi-line LubricationThe ILC multi-output pumps are applied where simultaneous lubrication is required at several points without using dispensers. Oil-based to lubricate the catenary and moving components, they may have different capacities. The grease versions are intended to be used in heavy-duty industrial sectors Fittings and Accessories

|