Prevent Gear Failure

| ADDINOL ECOGEAR M and S | |

| ADDINOL Eco Gear, with the innovative Surftec® formula against wear, is designed as high-performance industrial gear oil for modern gear efficiency. ADDINOL Eco Gear has achieved spectacular success for many years. Mining, cement, paper or sugar industries, ship gear units or wind power plants – ADDINOL Eco Gear impresses with outstanding results. ADDINOL Eco Gears success is unmatched and supported by well-known independent institutions, such as the FZG*.Eco Gear M is based is a mineral oil and Eco Gear S is the synthetic version. Both versions contain Surftec® as substance combination and adapts to the changing loads in gear teeth whilst bonding to the gear.ADDINOL Eco Gear M and S prevent the formation of both pitting and micro pitting as well as abrasive wear. The high performance gear oils safely protect against material removal and deterioration.Addinol Eco Gear Case Studies and technical download information…Mining bucket wheel excavators Bucket wheel excavators are among the largest mining equipment in the world. The 288 (288 excavator) by Krupp is in fact the largest excavator in the world and can move 240,000 tonnes of dirt. In 2006 a gear inspection was made on the main drive. Pitting of the gear teeth was discovered and as was metal wear in the filter. The oil was changed to Addinol Eco Gear 460M. To date no more pitting or failure has occurred! Read More… Container Ship Quarry Crusher Zinc processing plant Addinol Eco Gear is available from ISO VG100 to ISO VG 680 and available in 20L and 205L drums and BEST OF ALL available AUSTRLIA WIDE.

|

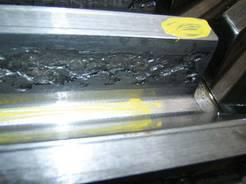

Addinol Ecogear M  Filter with wear particles  Pitted gear teeth  Stabilised gear teeth with Addinol Ecogear M |